Precision Systems

Case Studies

Project Name:

Johanssen Farm Lift Station

Location:

Sussex, WI

The Problem:

The Village of Sussex was adding a new lift station for a new residential development project. The developer wanted to have a station that would blend into the neighborhood, and greatly wanted to avoid an eye sore. In addition, the Village’s team wanted a station that would allow for easy accessibility with a permanently-mounted standby power system, as well as a design that could handle vibration occurring from a nearby quarry. The Village Engineer also desired single source responsibility for the design and manufacture of the complete station.

The Solution:

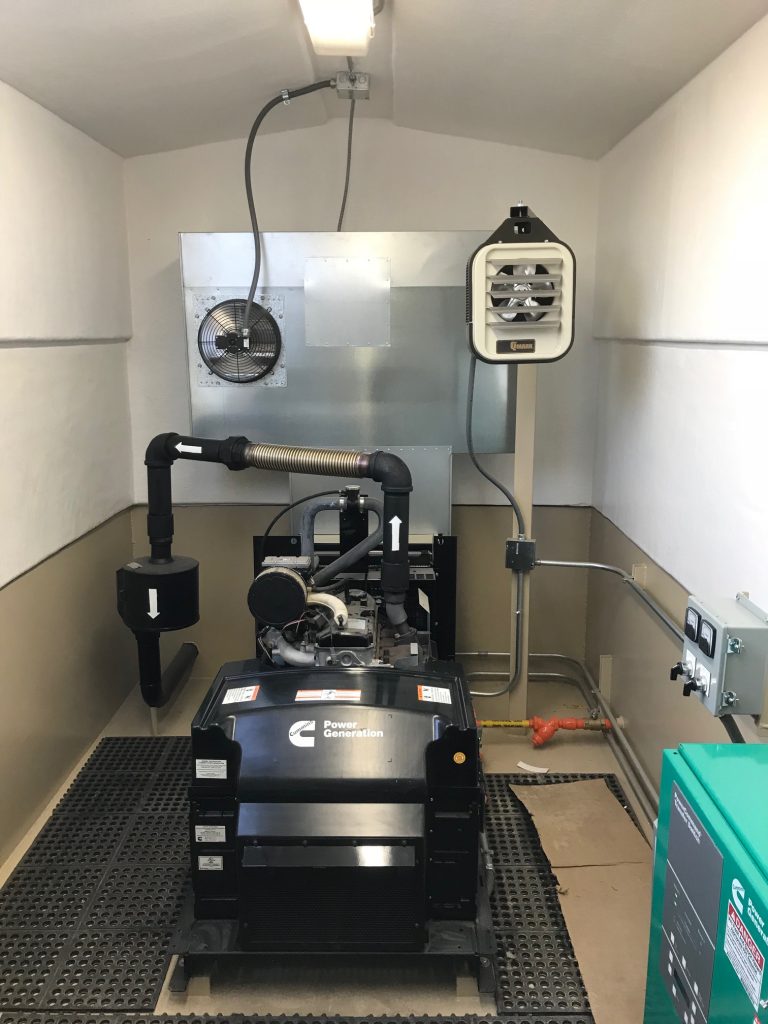

Reid Snedaker, in one of his final projects before retirement, recommended a Precision Systems’ Twin Pac which he knew would be able to incorporate several other vendors’ components to provide the complete station. With low-profile aesthetics, serviceability and a comprehensive design being of utmost importance to both the developer and the Village of Sussex, the Precision Systems’ Twin Pac was the clear choice to meet all of these needs. The Twin Pac model selected included internally-mounted Smith & Loveless vacuum-primed pumps. The Twin Pac station, which marries both the pumping system and standby power system in a single integrated unit, also enclosed the pump control panel, SCADA telemetry system, automatic transfer switch, and environmental controls. The control system was an Allen-Bradley PLC-based system by Primex that communicated with the Village’s existing SCADA telemetry. Furthermore, the Twin Pac’s enclosure is designed to protect not only the equipment but also the operators in the harsh winter months. To account for the very serious vibration issues from the nearby quarry, Reid recommended teaming with Watertronics to provide a very specialized HDPE wetwell that could be fusion welded to the HDPE forcemain thus eliminating vibration separation and deterioration.

Equipment Description:

-

Twin-Pac Partial-Bury Enclosure

-

(2) S & L 4B2D 7.5 HP Vacuum-Primed

-

Pumps Rated for 180 @ 55’ TDH

-

Duplex PLC-based Pump Control Panel

-

Village Telemetry System Panel

-

30 KW Natural Gas Generator

-

Automatic Transfer Switch

Precision Systems provided overall station design, including complete plans and specifications and provided coordination with the Village of Sussex, its consulting engineer and the developer. The Village of Sussex’s consulting engineer just needed to provide the necessary structural design for the concrete slab foundation for the Twin Pac to sit on based on local soil conditions. A key benefit to the single-source design and supply of this package system meant that ALL key components arrived to the jobsite factory-finished and tested both electrically and mechanically.

The Result:

Through coordination of vendors, we were able to deliver a complete station for the Village of Sussex that will serve them for decades to come. The HDPE wet well was installed during the initial concrete work, and with force main piping already in place. The station was then lowered onto the concrete pad, and positioned above the wet well. With the station’s controls integrated into their current SCADA system, the Village couldn’t be happier. They now have a safe and warm environment to perform any preventative maintenance, and they do not need to worry about the station going down in the event of a power outage.

Not only does the Twin Pac provide a fully integrated system with protection for their equipment and personnel, but it also provides clean look that hides the “dirty” work being performed.